Titan Load Monitors

Titan offers a full range of load monitoring solutions, from stand alone load monitors to comprehensive packages that can be individually designed and configured to suit your specific requirements. All of our products can be purchased as stand-alone systems or packaged in any combination.

We can provide load monitoring solutions to suit most makes and models of press including C-frame, straight-side, double action, multiple-stage transfer and hydraulic presses.

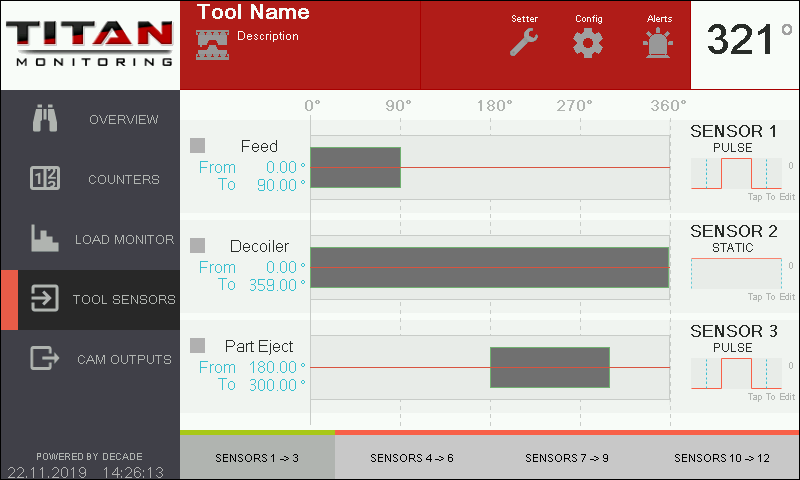

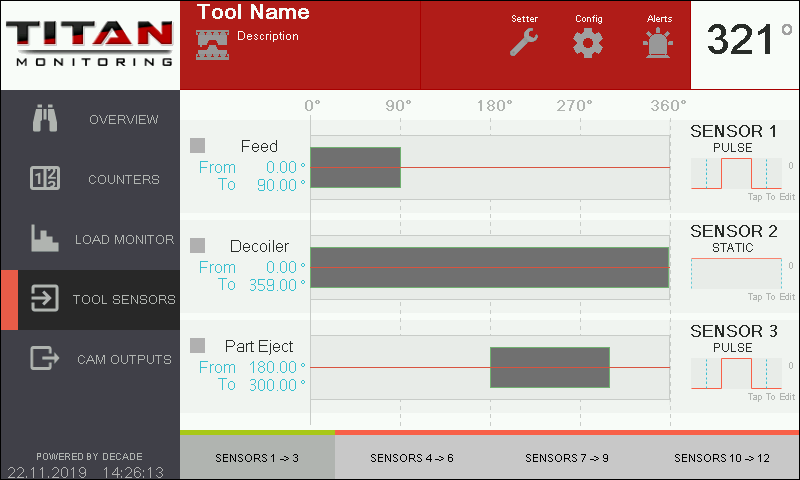

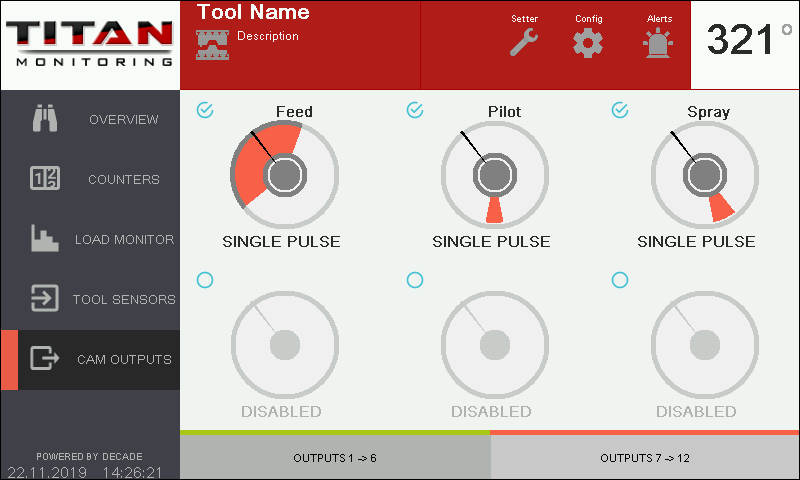

Electronic Cam Packages: Enable you to avoid the difficulties associated with adjusting cam boxes and physically moving cam lobes. Can be used for feed equipment, strip lubrication equipment and other ancillary equipment requiring a signal during the press stroke.

DLM: The DLM Series offers a 1, 2 or 4-Channel cost-effective digital power press load monitoring solution. It’s simple to use, offering a wide range of press and tool over and underload protection features.

| Feature | Description |

|---|---|

| Press Capacity Limit | |

| Tool Max Limit | Optional (enabled in setup) |

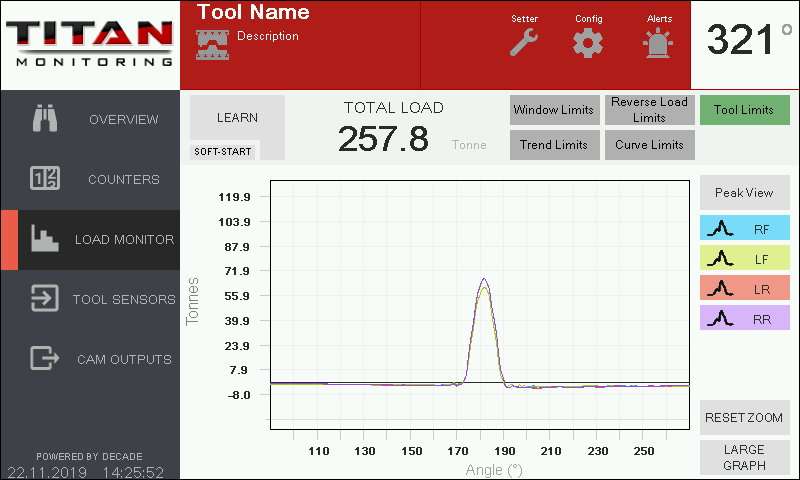

| Window Limit | Independent Upper and Lower band limits |

| Teach Mode | Window Limits can be taught rather than specifically entered |

| Soft-Start | On receipt of a Soft-Start signal will bring in the window limits gradually. |

| Bypass | The DLM can be put into bypass/ setter mode whilst the Bypass input is held on. |

| Data Log Output | Blow-to-blow Load values can be output via RS232 |

| DLM Link | Connect the DLM to a Windows PC for backup and restore functionality as well as viewing load curves in real-time |

| Security | Key access setup and rest |

All Titan products are UK manufactured and supplied with a full UK manufacturers 12 month warranty. Installation is carried out by Titan Engineers and all equipment is calibrated as part of the commissioning process.